Manufacturer for Growing Brands

From Sampling to Bulk · Built for Scaling Brands

- Factory-direct manufacturing · No trading company

- 100–5,000 pcs, Small to medium MOQ

- Clear production process

Our Activewear Manufacturing

These are the core activewear categories we manufacture for long-term brand partners.

Activewear Tops

- Running Tank Tops

- Running T-shirts

- Long-Sleeve Active T-shirts

- Compression Tops

- Quarter-Zip Active Tops

Activewear Bottoms

- Running Shorts

- 2-in-1 Running Shorts

- Training Pants / Joggers

- Compression Tights / Leggings

Zip Hoodies & Jackets

- Full-Zip Hoodies

- Zip-Up Training Jackets

Activewear Sets

- Long-Sleeve Top + Pants Sets

- Long-Sleeve Top + Shorts Sets

Fabric & Performance Focus

Materials selected based on performance requirements, end use, and production stability.

- Polyester / Spandex blends

- Moisture-wicking & breathable fabrics

- Stretch and recovery optimized for movement

Customization Options

Customization support designed to balance brand identity, cost structure, and production reliability.

- Printing (screen, heat transfer, sublimation when suitable)

- Label, hangtag & packaging customization

- Fabric sourcing support based on your target use

Brands Worldwide

From fast fashion to corporate programs — trusted for sampling, bulk production, and long-term cooperation.

Who We Work With

Have clear product direction or basic tech packs

Value long-term cooperation over one-off sourcing

Plan orders from 100 to 5,000 pcs per style

How Activewear Works

A clear process helps ensure stable quality and delivery timelines.

Requirement & design review

Initial discussion and assessment of your activewear design and technical specifications.

Sampling & testing

Creating samples and conducting thorough testing to ensure quality and fit.

Quality check & shipment

Final inspection and secure shipment to your desired location.

Bulk production

Efficient manufacturing of your activewear in the agreed-upon quantities.

On-site discussion during sampling stage

Direct communication between brand team and production team

Why Brands Work With Our Factory

We don’t chase one-time orders. We build production partnerships.

- In-house production with stable workers

- Direct communication, no middleman

- Clear responsibility from sampling to bulk production

- Focus on repeatable and scalable manufacturing

Factory in

Real Production Scenes • See Our Team & Workflow

Production & Sewing Line

What really matters for your brand — not just what looks busy.

- Not just people at machines — a structured workflow so your orders stay organized.

- Not just hands moving fabric — steps that help your sample and bulk match.

- Not just fast sewing — batch-focused production to keep fit and quality steady.

Material Handling & Cut Pieces

Not just piles of fabric — how materials are handled affects your order accuracy.

- Not just random cloth piles — fabrics sorted and labeled to avoid mix-ups.

- Not just stacked pieces — cut pieces grouped by batch to keep samples and bulk aligned.

- Not just a busy floor — clear zones and pathways help keep production on track.

Printing & Alignment

Not just print machines — how printing is done affects your fit, consistency, and delivery.

- Not just “stuck on” prints — careful alignment before pressing keeps logo positions consistent.

- Not just print after sewing — printing on cut pieces helps avoid distortion later.

- Not just adding a step — in-line printing as part of the flow helps keep your schedule on track.

Finishing & Checking

This is where most mistakes slip through — if no one is looking closely.

- Not everything passes just because it’s finished — each piece is handled before packing.

- Not all styles thrown together — colors and styles are separated before packing.

- Not checking after problems show up — this step exists to prevent them.

BEFORE YOU REACH OUT

This page is designed for long-term manufacturing projects. We may not be a good fit if you are looking for:

- Extremely low MOQ with frequent changes

- Price-only sourcing without production planning

- Long payment terms without prior cooperation

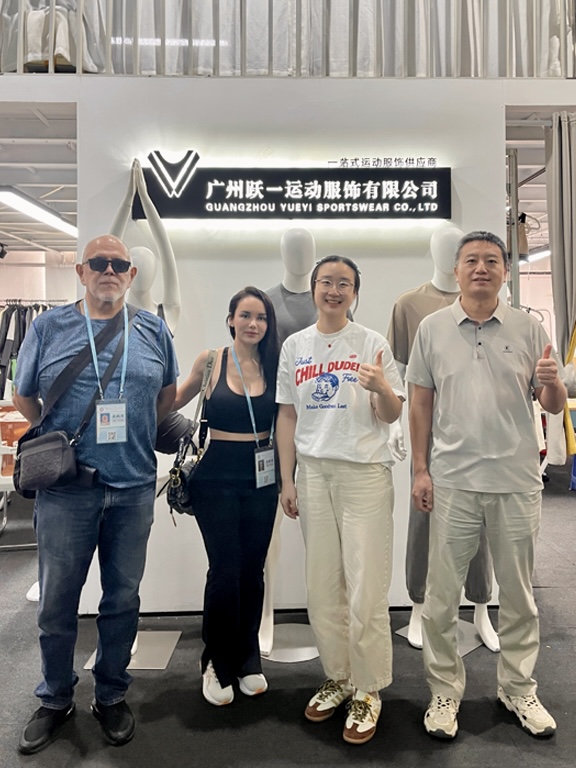

Real Clients. Real Visits.

Not stock photos. Not agents’ offices.

These are real clients visiting our factory in China.

2023.10.28 · India

factory tour & quality inspection

2023.10.28 · India

Fabric pre-shrinking machine inspection

2025.04.01 · Ireland

Client visit for sampling and quality review

2025.10.19 · Mexico

Client visit for sampling and quality review

2025.10.30 · India

Client visit for product development discussion

2025.02.24 · Saudi Arabia

Client visit for product development discussion

A Stable Team You Can

Most of our team members have worked together for 5–10 years, ensuring stable communication, consistent quality, and reliable delivery.

Sunny

Sales & Project Lead

Oversees client communication and project coordination

10+ years in apparel export & factory operations

Hebe

Sales

Handles daily inquiries and sampling follow-up

With Yueyi since 2022

Xiao Wang

Pattern Maker

Responsible for pattern development and fit accuracy

10+ years in apparel pattern making

Song Chen

Merchandiser

Manages bulk production, materials & delivery schedules

10+ years in garment production

Hai Qiu

Merchandiser

Coordinates factory execution and quality control

5+ years handling overseas orders

Compliance & Factory

Audited and approved by global brands and independent inspection bodies.

SMETA Audited (2022–2024)

Bureau Veritas Audit (2021)

Global Recycled Standard

REPREVE®

Global Organic Textile Standard

LYCRA® SPORT

Start Your Project

Tell us your product type, estimated quantity, and timeline. Clear information helps us respond faster and more accurately.